This process is called subtractive production, and computer programs are used to regulate device Device actions for improved CNC machining. The most common varieties and processing processes for CNC device equipment include things like milling, turning, grinding, and EDM.

Higher-overall performance sporting activities & motorsports manufacturers generally make an effort to increase the effectiveness of their solutions by lowering their body weight.

Conserving money is also obtained by maintaining section repositioning into a minimum. Machining at 5-axis and higher than can from time to time be far more cost-effective on multi-faceted geometries since it gets rid of the necessity to manually reposition the element.

The wire EDM way of machining is often sluggish and high priced relative to other processes, plus the choice of materials which can be used is shortened as they need to be electrically conductive.

By changing the proportional coefficient and integral time of the speed regulator, the servo procedure can realize the very best overall performance with high dynamic response and no oscillation.

To assist you to continue to keep the cost of CNC machined parts into a minimal, we’ve compiled an index of style and design guidelines.

Using CNC device instruments for machining can precisely compute the working hours of one product or service and fairly organize generation.

Tapped holes not explicitly termed out as Capabilities over the quoted CAD model might be machined towards the diameters specified in that model.

Reduce dust from coming into the numerical Command product: Dust and steel powder can easily induce a lessen in insulation resistance concerning parts, resulting in element failure or destruction.

Device instruments is often categorised into two groups based upon the choice and Management method: conventional machine applications and CNC superior-precision device equipment.

The self-diagnosis of CNC technique can not only Exhibit fault alarm information on CRT Screen, but also present machine Resource parameters and status data in the shape of multi webpage “diagnostic handle” and “diagnostic information”.

On the whole, CNC device equipment really should be Outfitted with enough equipment to completely use their functions, enabling the machine to process a number of goods and steer clear of idle time and squander.

There will almost always be some design and style limitations due to Software accessibility, Even though the degree of Find out more the impact is relative to the quantity of axes within the equipment. Quite simply, the greater axes used, the more elaborate the characteristics may be realized.

Therefore, the labor depth is noticeably lessened, and the equipment Resource operator’s work tends toward intellectual operations. In addition, CNC equipment instruments commonly process in an enclosed manner, which is clean up and Harmless.

Brian Bonsall Then & Now!

Brian Bonsall Then & Now! Michael Bower Then & Now!

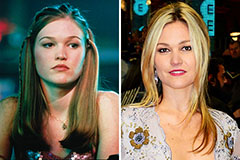

Michael Bower Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!